Bakery Filling Cream

Potential Applications

If a dispersion of Neocel® is below pH around 3.5, the addition of a protective gum (e.g. xanthan gum) is suggested to prevent flocculation.

Recommended Type

Recommended Usage Level

0.8-1.2%. The usage level depends on the type, application and other combined hydrocolloids.

Bakery Cream Filling

Processing Procedure

Add milk powder, sugar and modified starch into the dispersion, and mix for 2 minutes.

Heat the mixture up to 85°C for 1 minute.

Cool down to ambient temperature.

Pour it into a container.

Store in 4 °C.

Enhancement of Baking Stability

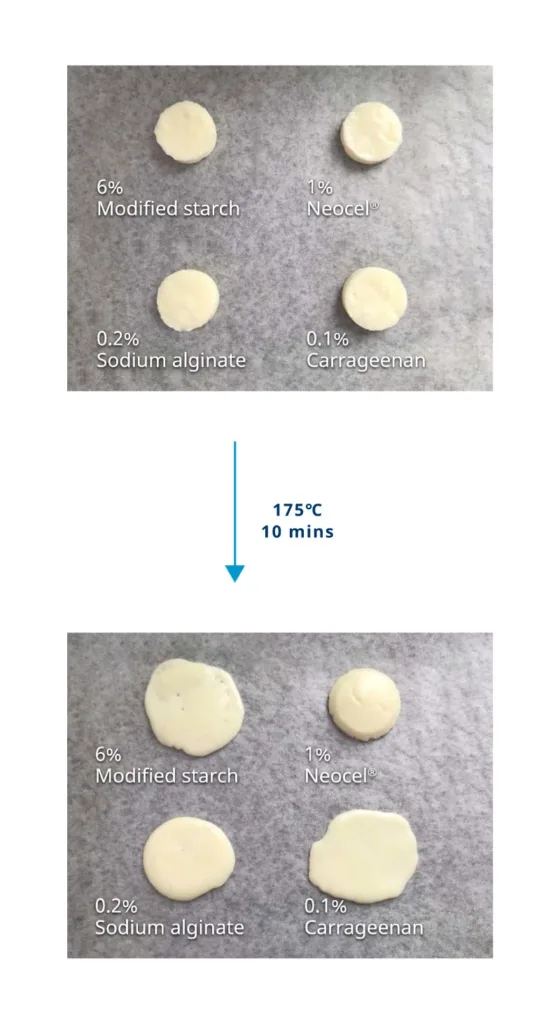

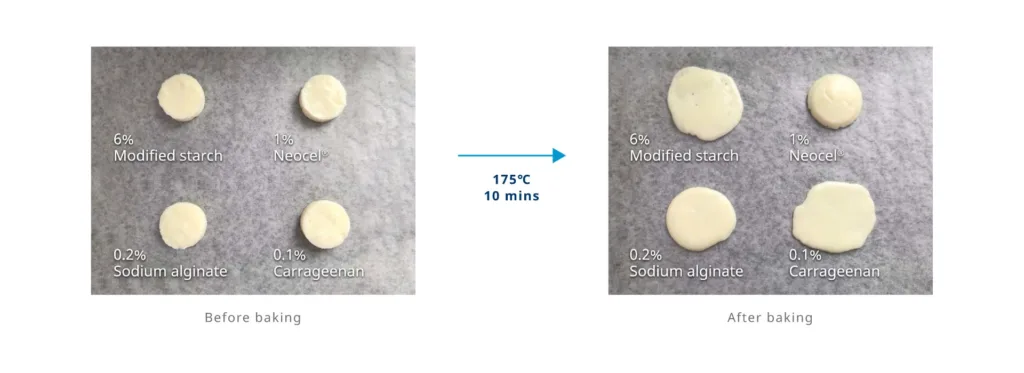

Comparison of Different Hydrocolloids on Bake Stability

Cream fillings made with several stabilizer, including modified starch (E1442), Neocel®, sodium alginate and carrageenan were baked at 175°C for 10 minutes. The result showed that the sample made with Neocel® did not collapse after baking process, suggesting that Neocel® has better bake stability among these commonly used stabilizers.

Great Oral Perception

In addition to improving bake stability, Neocel® also brings great mouthfeel into bakery fillings, which is attributed to the special thixotropic behavior of Neocel®. The shear thinning phenomenon is one of the key features of Neocel®, which makes the products with it exhibit great perception in mouth.